scara robot pdf

As we know the workspace dimensions ie. EFEM with SCARA Robot Minimal elbow motion required Space reduction PDO PDO EFEM with traditional R-theta Robot Minimum radius turning circle R-Theta vs.

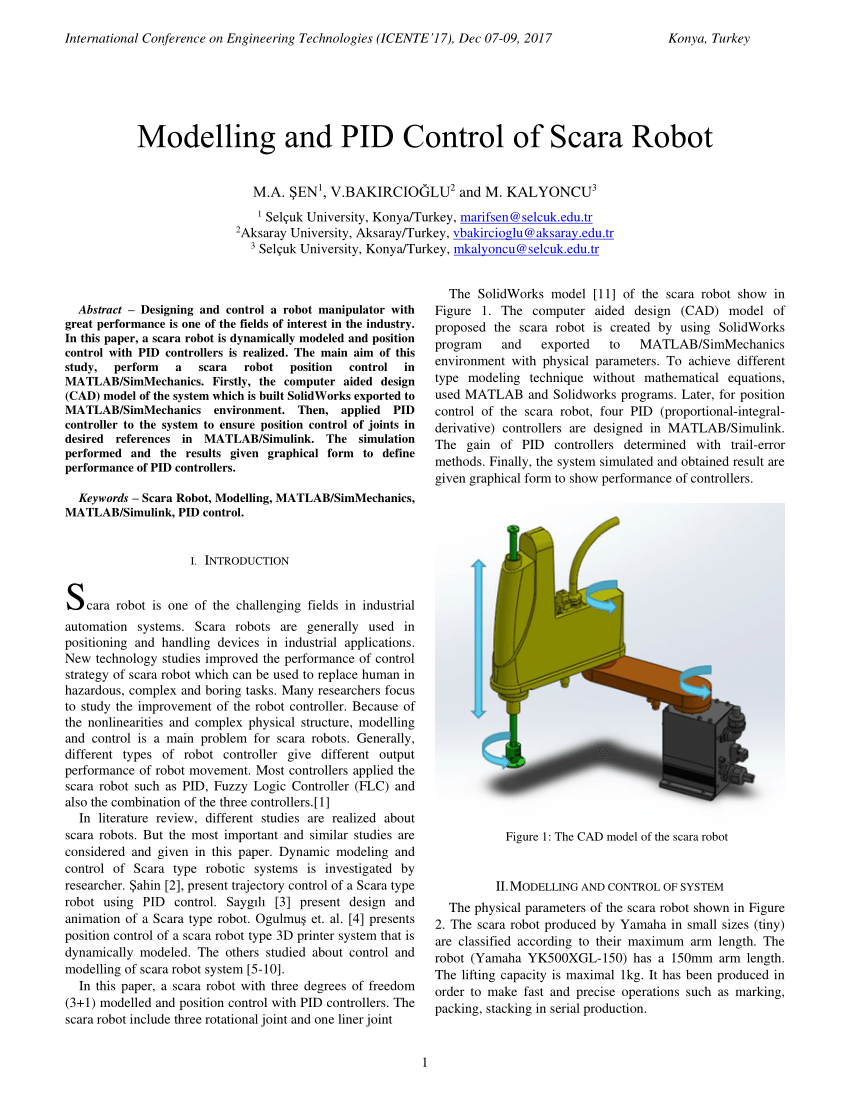

Pdf Modelling And Pid Control Of Scara Robot

SCARA Robot Controller.

. This manual describes the SCARA Robot developed by HIWIN whose structure includes the body the control panel the Teaching Pendant optional the connection cable and the software. Umfassende persönliche Beratung und einfache Integration in bestehende Steuerungskonzepte. SCARA Robot Software-RS403 RS406 User Manual Original Instructions.

The brain of this SCARA robot is an Arduino UNO board which is paired with a CNC shield and four A4988 stepper drivers for controlling the stepper motors. Quick and easy integration Prepared ex works to integrate peripheral technology safely quickly and easily for minimal impact upon downtime and ease of integration into existing operational infrastructures. SCARA is applied pick and place type operations ato u-tomated palletizing and de-palletizing operations assembly machining operations etc.

PDF 1689KB TSAssist - Robot Programming Assist Tool. Then in third phase which is the product generation the chosen design of the SCARA robot is fine-tuned. Stress analysis using finite element analysis is carried out before a prototype is developed.

The robot has 4 degrees of freedom and its driven by 4 NEMA 17 stepper motors. Sample 2-FOUP Layout IR-820 can improve your footprint and reach higher throughput. IR-820 SCARA 10 footprint shrinkage.

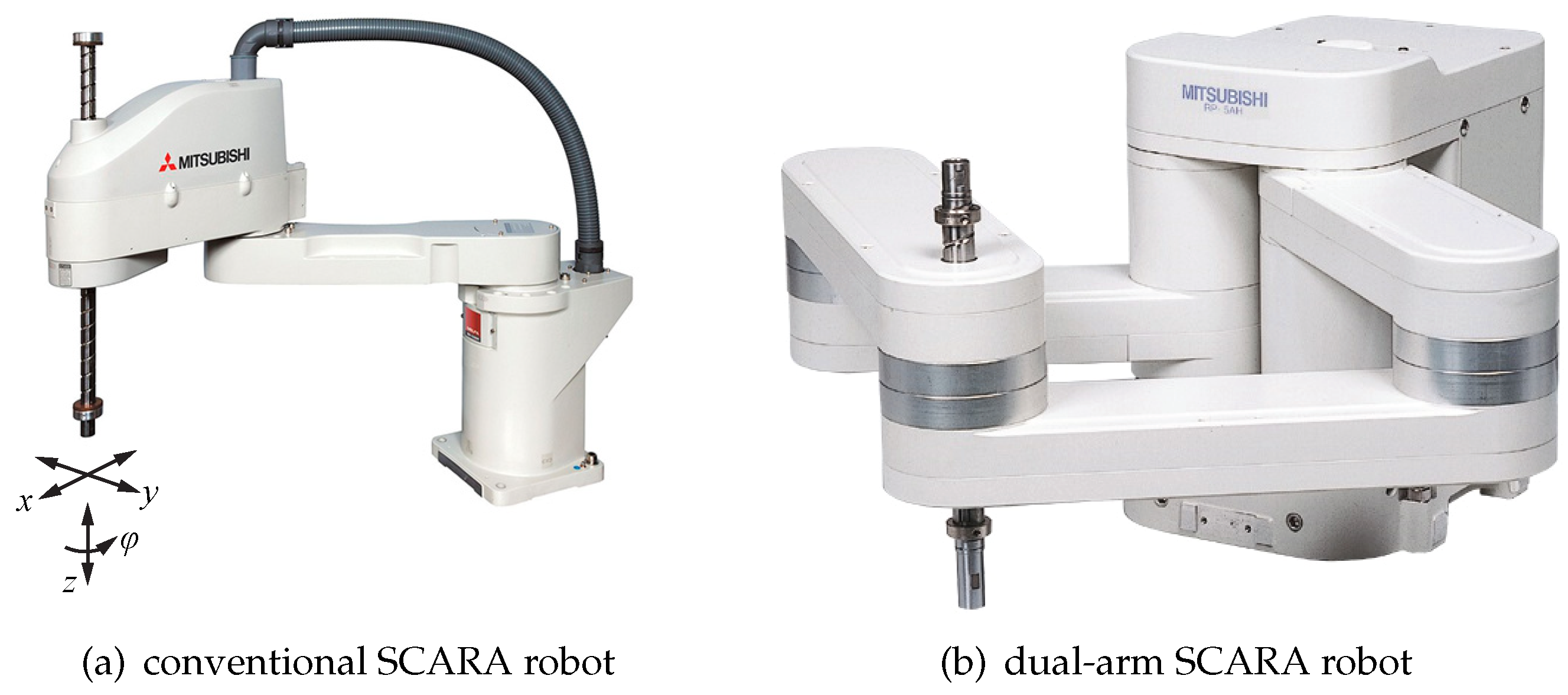

1 Delta SCARA Robot DRS Series Current trends affecting manufacturing industries include labor shortage harsh environment short commodity cycles small-volume and large variety orders and frequent changeovers. SCARA robots are regularized for use in handling and assem-bly. Then forward and inverse kinematic equations of the robot are derived by using D-H parameters and analytical methods.

INDUSTRIE 40 Best Partner Multi Axis Robot Pick-and-place Assembly Array and packaging Semiconductor Electro-Optical industry Automotive industry Food industry Articulated Robot Delta Robot SCARA Robot Wafer Robot Electric Gripper Integrated Electric Gripper Rotary Joint Single Axis Robot Precision Semiconductor. Low cost high performance model YK400XE-4 Product Lineup YK-X Series YK-TW Orbit type YK-XGYK-X Completely beltless model Note YK-XE Low cost high performance model YK-XGS. The SCARA Robot is designed for 1200500 mm workspace dimension.

Completely beltless structure pursues the features of SCARA robots to their utmost limits. We know the end determining the joint angles consider the motion of. PDF 1167KB SCARA Robot THE400.

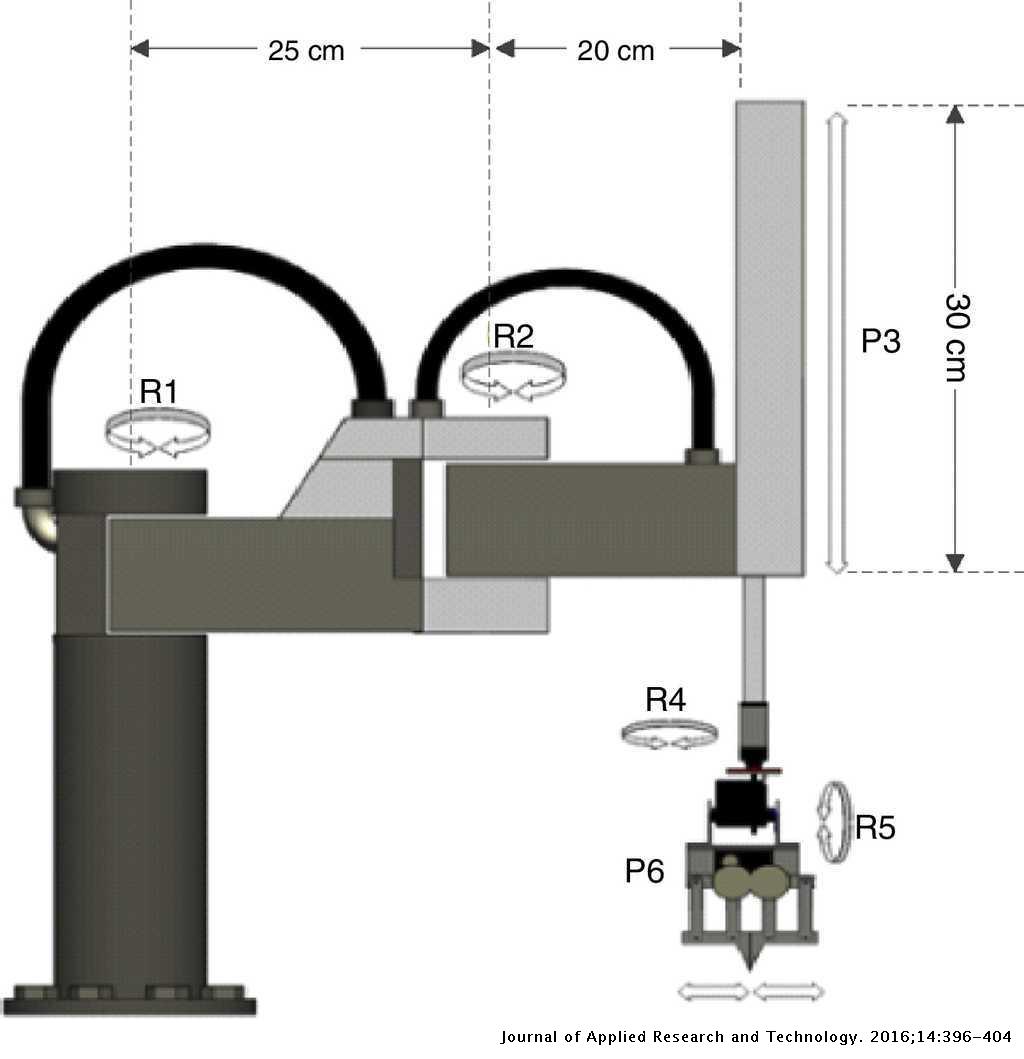

Since the first SCARA robot called CAME was produced in 1979 some 30 years of SCARA robot innovations have continually appeared. Additionally it has a small servo motor for controlling the end effector or the robot gripper in this case. This Scara robot consists of 3 degrees of freedom that include two rotary joints with a prismatic joint.

This modeling is important because IT allows studying the behavior of the manipulator under a control action it generates an interaction between the robot and the virtual simulation environment. INDUSTRIE 40 Best Partner Multi-Axis Robot Pick-and-place Assembly Array and packaging Semiconductor Electro-Optical industry Automotive industry Food industry Articulated Robot Delta Robot SCARA Robot Wafer Robot Electric Gripper Integrated Electric Gripper Rotary Joint. Firstly the SCARA robot is designed in accordance with the mechanical calculations.

The assumptions made are. PDF 784KB SCARA Robot THL Series. Three DC gear motors were utilized to control the actuator joints of the robot.

SCARA ROBOTS Arm length of 120 mm to 1200 mm full-selection of lineup is top in the world. The KR SCARA robot can be used across the entire temperature range between 5 and 40 Celsius IP protection class 20. Ad Passende kartesische Roboter Tisch- und SCARA-Roboter für jede Produktionsanforderung.

In response production lines. SCARA Robot is placed between center of workspace and it is kept away by 100 mm distance from the workspace. Compact high-performance SCARA robot with unique workspace design RS-SERIES SPECIFICATIONS RS3 RS4 Arm length 350 mm 550 mm Repeatability Joints 1 2 0010 mm 0015 mm Payload Rated 1 kg 1 kg Maximum 3 kg 4 kg Standard cycle time1034 sec 039 sec Installation environment Standard Cleanroom2 ESD Available controllers RC180 RC700A.

Manufacturing cell operation depends on parts to be assembled. This research paper focuses on a single cell manufacturing machine setup that can be programmed according to requirements to perform certain processing functions. Presents the structure of a SCARA manipulator.

The modeling of the SCARA robot manipulator is based on the kinematics and dynamics of its morphological structure see Fig. The software is developed according to the obtained Cartesian velocities from joint velocities and joint velocities from Cartesian velocities. Sample 3-FOUP Layout NOTE.

PDF 1258KB SCARA Robot THL1200. PROGRAMMING A SCARA ROBOT FOR A MANUFACTURING CELL TO ASSEMBLE AND PRODUCE MEDICAL DEVICES Abstract. It has a RRP configuration where the first two joints are rotary followed by a third prismatic joint.

Off shelf parts are. The direct and inverse kinematics dynamics of the robot are then modeled. A user who purchases the robot can operate and maintain the robot via this manual.

PDF 9053KB SCARA Robot TH Series Catalog PDF 8266KB High-Performance teach Pendant TP3000. SCARA robot is chosen after making concept evaluation in the conceptual design phase. Ad Passende kartesische Roboter Tisch- und SCARA-Roboter für jede Produktionsanforderung.

Umfassende persönliche Beratung und einfache Integration in bestehende Steuerungskonzepte. The rest of the paper is organized as Literature survey CAD modeling and analysis of SCARA manipulator. 12 IR-820 fits in the smallest.

These SCARA robots have undergone countless modifications in an ever changing marketplace and amassed a hefty record of successful products making them an essential part of the YAMAHA robot lineup.

Pdf Design Of An Economical Scara Robot For Industrial Applications

Jsr4400n Series Scara Robot Janome Industrial Equipment Pdf Catalogs Technical Documentation Brochure

Js3 Series Scara Robot Janome Industrial Equipment Pdf Catalogs Technical Documentation Brochure

Pdf Modelling And Control Of A Scara Robot Using Quantitative Feedback Theory Semantic Scholar

Scara Robot G Series Machine Vision And Optical Quality Control

Design Construction And Control Of A Scara Manipulator With 6 Degrees Of Freedom Journal Of Applied Research And Technology Jart

Robotics Free Full Text Simulation Assessment Of The Performance Of A Redundant Scara Html

Pdf Active Disturbance Rejection Control Of A Scara Robot Arm Semantic Scholar

Spt Rls20 804st9p5 Epson Ls20 Scara Robots Scara Ls Series Scara Robots Robots Support Epson Us

Scara Robotic Arm Googol Technology Hk Limited Pdf Catalogs Technical Documentation Brochure

Hiwin Scara Robot Rs405 Lu User Manual Pdf Download Manualslib

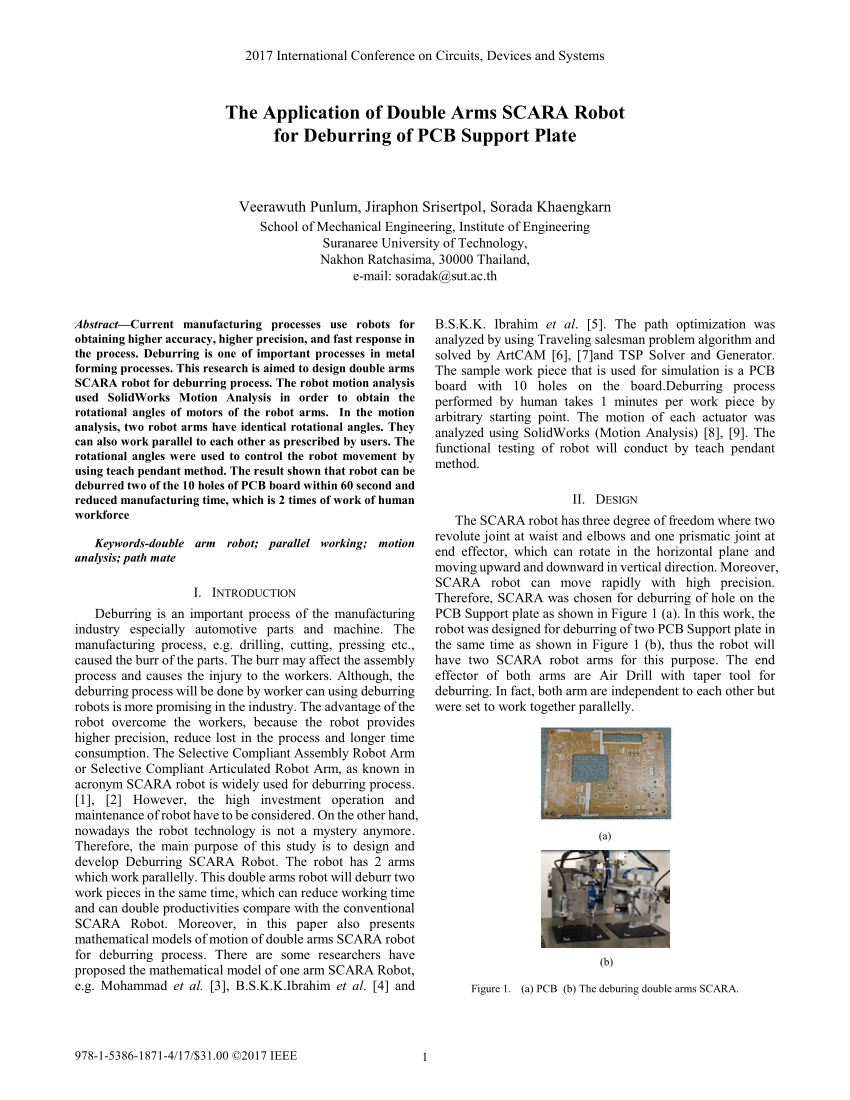

Pdf The Application Of Double Arms Scara Robot For Deburring Of Pcb Support Plate

Scara Robots Yamaha Motor Co Ltd Pdf Catalogs Technical Documentation Brochure

Large Type Scara Robots Yk Xg Industrial Robots Yamaha Motor Co Ltd

Pdf 653 The Retrofitting Of Aub S Ibm 7540 Scara Robot Prasanna Thillai Academia Edu

Dual Arm Scara Robot Duaro For The Food Industry Kawasaki Robotics Gmbh Pdf Catalogs Technical Documentation Brochure

Adept Ecobra 600 Scara Robot Omron Electronics Gmbh Pdf Catalogs Technical Documentation Brochure

Comments

Post a Comment